Search

Driving Dynamics

Hydraulic motors are integral to the driving dynamics of construction equipment, providing the necessary power, precision, and control for a wide range of applications.

We focus on embedding sustainability into design and manufacturing

Mukul Dixit, Director – Sales & Marketing, Global Construction Industries (GCI), Caterpillar India, speaks on various models of new-age excavators launched by the company, and how are these excavators equipped to deal with intricate projects.

We’re also moving towards fully electric machines

In the bustling world of crushing and screening machinery, Terex India stands as a prominent player. We sat down with Neil Robinson, Product and Applications Manager, Powerscreen, to discuss their approach to the Indian market and their commitment to delivering efficient, sustainable, and technologically advanced solutions.

Volvo reveals 50-Ton EC500 next-gen excavator

To have Volvo smart view with obstacle detection technology

Volvo CE unveils prototype of new EC500 crawler excavator

Volvo CE provided the first look at a pre-production model of its new EC500 excavator today at the CON EXPO trade show in Las Vegas, North America.

Volvo CE unveils prototype of new EC500 crawler excavator

Volvo CE provided the first look at a pre-production model of its new EC500 excavator today at the CON EXPO trade show in Las Vegas, North America.

Volvo CE unveils prototype of new EC500 crawler excavator at ConExpo

This heralds a new generation of excavators, with improvements across cab design and operator interface, safety and productivity.

Improving efficiency

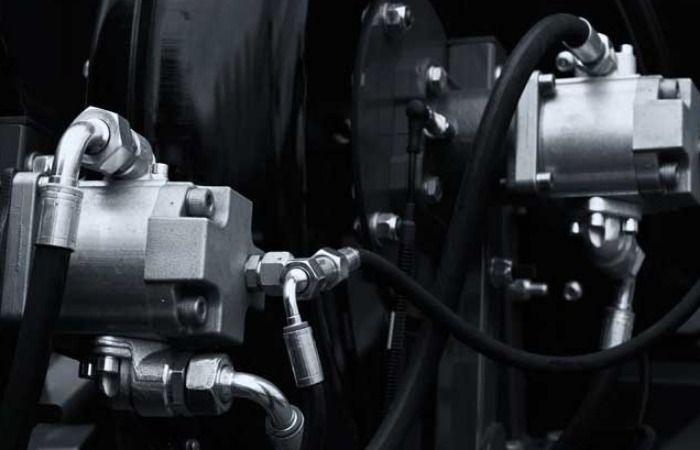

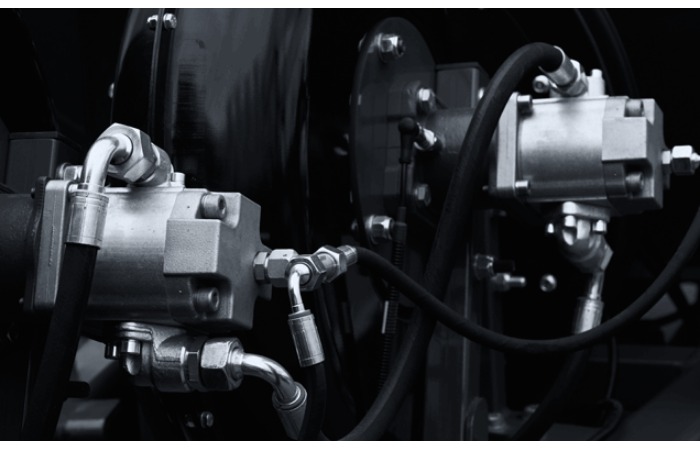

Hydraulic motors are among the most commonly used motors across a wide range of industries.

Motion launches Mi Fluid Power Solutions

Motion Industries Inc., a distributor of maintenance, repair and operation replacement parts, and a provider of industrial technology solutions, has formed a new fluid power business brand: Mi Fluid Power Solutions (Mi FPS).

Towering up

Crawler cranes are expected to see a surge in demand with the spurt in infrastructure development projects.

Tech Drives Backhoes

Backhoe loader manufacturers are leveraging digital technology by integrating Big Data and the Internet of Things in their models.

Backhoe Loaders Bouncing Back

In the current market conditions, the customer focus will be on equipment with better productivity and cost saving. Backhoe loader with its multi-utility advantage and competitive price will drive the demand in the current market scenario.

Caterpillar Hydraulic Excavator

Caterpillar Inc launched its new hydraulic excavator, Cat? 313D2 L, in India. Manufactured at the Tiruvallur facility, the new excavator has unmatched versatility, improved controllability, easy operation and a comfortable redesigned operator station, according to the company.

Caterpillar Hydraulic Excavator

Caterpillar Inc launched its new hydraulic excavator, Cat? 313D2 L, in India. Manufactured at the Tiruvallur facility, the new excavator has unmatched versatility, improved controllability, easy operation and a comfortable redesigned operator station, according to the company.

Less Downtime, More Go Time

One of the key growth engines of India has been its robust and thriving construction sector. It is expected to grow at an annual average of 6.6 per cent between 2019 and 2028.

TECH-MOVES

With the government plans to invest Rs 102 trillion in infrastructure development in the next five years, the demand for construction equipment will be immense.

Caterpillar launches new hydraulic excavator in India

Caterpillar Inc launched its new hydraulic excavator, Cat? 313D2 L, in India. Manufactured at the Tiruvallur facility, the new excavator has unmatched versatility, improved controllability, easy operation and a comfortable redesigned operator station, according to the company.

Caterpillar launches new hydraulic excavator in India

Caterpillar Inc launched its new hydraulic excavator, Cat? 313D2 L, in India.

Intelligent Maintenance

Mining companies often go to greater expenses to keep their giant equipment healthy. The cost of achieving the crucial reliability can be reduced considerably through intelligent maintenance.

Couplings for Diesel Engines

KTR Couplings (I) Pvt Ltd, established in 1998 at Bhosari, Pune is a 100 per cent subsidiary of KTR Systems GmbH Germany, a well-known name worldwide for couplings and power transmission products.

Wipro-Kawasaki plant to start production from April

The new plant of Wipro-Kawasaki joint venture to manufacture hydraulic pumps and motors for construction machinery was inaugurated at Bidadi, near Bengaluru.

On Strong Foundation

Foundation equipment segment is back on action with a lot of equipment busy at various project sites across the country. The trend is expected to continue for the next few years.

High performance rotary oil seal

Low-speed/high-torque (LSHT) hydraulic motors are one of the most cost-effective and dependable parts of a hydraulic system. Offering many advantages over a high-speed motor and gearbox speed reducer.

Excavators Excel

Driven by the infrastructure development activities in the country, hydraulic excavators recorded a sharp growth in 2016 compared to the previous year. The positive trend is continuing this year also with a 26 per cent growth in the first four months.

Smooth, Safe and Efficient

Condition-based maintenance has been carried out since the early1950s across industry segments of mining, dredging, cement, power and paper manufacturing. In fact, wherever there are expensive machines working in severe duty cycles, condition-based maintenance is quite a normal feature in modern maintenance practice.

Electric Throttle Actuators

The latest electric throttle actuators provide a cost effective way to control engine speed on mechanical diesel engines. Compact and easily installed, they enable greater freedom of machine design and the use of more ergonomically optimised controls.

Liebherr to showcase innovations at Bauma China 2016

At Bauma China 2016, Liebherr Group will showcase the latest technologies and developments in construction machinery and components.

O&M Training by OEM Dealership

India is on the path of modernisation with rapid progress in infrastructure development. The investment in the infrastructure sector in India is pegged at Rs 1,80,000 crore.

Innovations in CE

The construction equipment (CE) manufacturers are closely monitoring the needs of the customer and industry, and are investing considerable amount in R&D to bring innovation in technology, products and services.

Optimising Fuel Efficiency

Transmission solutions play a vital role in the overall performance of an equipment. Availability of the latest technologies in transmission solutions have helped OEMs to improve the efficiency level of their equipment.

ZF transmissions are tailor-made for different applications

ZF has recently strengthened its business development footprint for the Indian market through establishing a local engineering resource. Suresh KV, President for ZF in India elaborates on the company?s solutions to the CE industry.

Dozco now markets its own manufactured products in global market

Dozco has 60 per cent of its total business from parts supply in the after sales market for all kind of construction and mining equipments and 40 per cent from equipment and its parts for which Dozco is authorised distributor.

Moulding the Future

Dozco India has been providing hands-on training to the staff of Dozco and its customers through its well-equipped state-of-the-art training centres at Dhanbad and Visakhapatnam.

O&M Training by OEM Dealership

Svenska Institute of Technology is essentially formed to prepare young engineers and technicians for a bright future in maintenance of construction, mining and road equipment.

The time has come

As per one of the recent reports ?impatience was creeping in among business men as nothing has changed on the ground in the first nine months of Modi government?; and if we assess the time period for this ?impatience?, it is not the couple of months these ?business? communities have looking for some action from the government, but it has been over a couple of years! Opportunities are aplenty.

Make in India

Prime Minister Narendra Modi has launched an ambitious campaign ?Make in India?, which aims to turn the country into a global manufacturing hub. The campaign projects India as an investment destination and develop, promote and market India as a leading manufacturing destination and as a hub for design and information.

Electrification of Tractors

Electrification of tractors?as a farm equipment?may be tougher than electrifying cars and commercial vehicles. However, it is likely to become a reality, writes Bhushan Mhapralkar. Unlike passenger cars or trucks, tractors have several different standardised interfaces.

Case shows its strength at bauma

Case Construction Equipment had centre stage at this year's bauma exhibition in Munich, showcasing its wide variety of equipment and demonstrating the range of machinery on offer to customers around the world.

Golden Award for CASE

The Golden Award to CASE's WX210 wheeled excavator is a testament to the company's innovation and ability to anticipate the specialist needs of its customers.

The innovative EcoPlus package achieves fuel savings of more than 20 per cent

The new training centre at Wirtgen India is equipped with a high-end multimedia system, two generously dimensioned training rooms, each one large enough to carry out training directly on a Wirtgen surface miner or a large V?gele asphalt paver,

World's first hybrid reach stacker

The new reach stacker, 4531 TB5 HL T, promises fuel consumption and emissions with at least 30 per cent while offering improved performance. KONECRANES has recently announced the introduction of the world's first hybrid reach stacker,

Pumping solutions

Back in the day, concrete pumps were used mainly in metros and major cities; in recent years, however, the industry has witnessed increased demand for concrete pumps in the Tier II and Tier III cities;

We are very focused on fuel-efficient concrete pumps

We are offering boom pumps starting from 20 m class up to 43 m class. In future, based on the customer need and availability of suitable truck chassis, we will offer boom pumps with a reach of more than 43 m,

New Dash 3 Pavers

The leader of the world paver market is presenting the new Dash 3 generation of pavers for the first time at this year's Intermat exhibition in Paris, France. A new generation of engines known as I-engines ensures higher efficiency and lower pollutant emissions, as well as lower noise levels. But Dash 3 encompasses more than just conversion of the engines to meet statutory requirements

We deliver fuel efficiency across all elements of our machines.

Volvo CE takes a holistic approach to fuel efficiency. We deliver fuel efficiency across all elements of our machines via engines, systems, operator behaviour and future technologies, while increasing productivity for our customers, says AM Muralidharan, President, Volvo Construction Equipment. Excerpts from the interview.We have seen a slight increase in the demand for compactors/pavers during Q4 but the market is still low compared to past years. If the requirement goes to double digit numbers

Dynapac launches new CA Rollers

Dynapac?s fifth-generation of single-drum vibratory rollers were most enthusiastically received.

Efficient and economical equipment for ICE

New solutions for big diameter drilling to micro piles and sheet pile installation. In the changing Indian construction environment, companies are continuously searching for new

Improving Productivity

The New Age hydraulic lubricant Mobil DTE 10 Excel 32 delivers top class energy efficiency in the most severe operating conditions of complex machines such as metal cutting tools.

Dash 3 Pavers from V?GELE

The leader of the world paver market is presenting the new Dash 3 generation of pavers for the first time at this year?s Intermat exhibition in Paris, France.

Fuel and Energy Efficient Machines

In an intensely competitive market, OEMs are no more just technology providers; rather, they are keen on providing total solutions specific to a project.

We have exciting product launches planned for this year

LiuGong excavator provides the highest productivity in its class due to effortless hydraulic con?trols, and spacious cabin. Liugong lays lot of emphasis on operator comfort in order to increase operator?s efficiency,

We have exciting product launches planned for this year

LiuGong excavator provides the highest productivity in its class due to effortless hydraulic con?trols, and spacious cabin. Liugong lays lot of emphasis on operator comfort in order to increase operator?s efficiency,

Compacting Technology Set to Improve

The new trend in technology is faster compaction by achieving the required density at a lower operating cost. Also, the latest equipment is designed with features to improve operator safety, comfort and maintainability.

The Challenge of Keeping Hydraulic Equipment Clean

Hydraulic equipment manufacturers are working round-the-clock to be the first to bring new 'must have' technologies to the market and fluid manufacturers are in test labs around the globe developing new solutions and preparing for the challenges of tomorrow.

Schwing Stetter will launch 20 new products at Excon

At Excon 2011, Schwing Stetter will launch 20 new products, targeting everyone from small customers to large corporate across various segments. You can expect us to demonstrate the next level of mechanisation of concreting," says Anand Sundaresan, Managing Director, Schwing Stetter,

Caterpillar has vibratory soil compactors in the operating weight range of 4.5T?18.5T

The popular model being offered in India is the CS533E (11T Class) which is required to meet the National Highway Project requirements in India,? says Pankaj Dara, Associate Vice President - Construction, TIPL. 0 - - 15633 14 102 2011-05-02 00:00:00.000 Equipment India Hamm is the technology leader in compaction equipment

?Our existing manufacturing facility can produce 400 machines annually and plans are on for further expansion in the coming years,? says Girish Dixit, Head - Engineering & Design, Wirtgen India. In a freewheeling chat, Girish speaks about the industry trends.

Tell us about the range offered in compaction equipment and also their unique features?

Wirtgen India offers Hamm-11T soil compactor, 9T asphalt compactors and 24T pneumatic tyre rollers (PTR) for the Indian market. Hamm compactors come with German design and technology mainly featuring excellent operator comfort and safety. The equipment are powered by a fuel-efficient and highly durable water-cooled engine.

Hamm is the technology leader in compaction which has been awarded many design prizes for its latest innovations. Recently, it was awarded iF-Gold award 2010 also called the Design Oscar for new HD+ series of asphalt compactor. The GRW 280, rubber-wheeled rollers received the iF Design award 2010.

Higher quality level of the components used in Hamm compactors increases the durability of the equipment. Better serviceability and reduced maintenance frequency with less fuel consumption results in the lower operating cost of the equipment.

What is the existing manufacturing capacity for these product lines?

Our existing manufacturing facility can produce 400 machines annually and plans are on for further expansion in the coming years.

What is the rental scenario for these products?

Currently, Wirtgen India is not in the rental market and is only selling the new equipment in the retail and corporate segments, rental companies.

Are these products compliant with the Bharat stage III emission norms?

Yes, the equipment built after April 2011 will comply with Bharat stage III emission norms.

How do you look at the replacement/ repowering market for the units sold which are not complying with Bharat stage III norms?

As per the regulations, no replacement/re-powering is required for the units built with Bharat stage II norms.

Why vibratory compactors over static ones and what is the vibration effect in compaction over the static loading?

Vibratory compactors develop dynamic force in addition to the static load and total applied force is the sum of dynamic force and the static weight of the machine. For example, Hamm 11T soil compactor generates 24T dynamic force and with 6.8T static weight at the drum will induce 30.8 tonne load on the ground. The advantage of using 11T vibratory soil compactor versus 30 tonne static compactor is evident from this.

The vibratory compactor with drum vibrating at higher amplitude will result in compacting the higher lift thickness and achieving the required density compared with the static roller. In the static roller, the linear load is not uniform over the width of the machine (one front roller and two rear rollers) which results in uneven mat finish. In the vibratory compactors, the linear load is uniform along the width of the drum.

To what extent do soil conditions determine the selection of compactors? Could you tell us the reasons?

Type of soil and conditions like moisture content decides the achievable density within the required number of passes. It is important to select the suitable compactor which will develop the required force to achieve the density with lesser number of passes on the appropriate lift thickness.

What determines the maximum achievable density?

Density depends on the soil characteristics (type of soil) and optimum moisture content (OMC) present in the soil. Generally, 95 to 100 per cent density can be achieved with 11T soil compactors on the appropriate lift thickness.

?To have maximum return on investment, the equipment should have maximum productivity and less rework,? says SM Roy, Chief Executive Officer, Lanco Infratech. In an exclusive chat with Equipment India, Roy elaborates on the evolution of compacting and grading technologies. Excerpts from the interview.

How, over a period, have the methods of compaction and grading evolved and to what extent does the contracting fraternity use the advanced equipment and methodology?

The first road roller was horse-drawn; this was followed by steam and diesel rollers. For a long period, static compactors of various sizes were used. The introduction of vibratory compactor in 1946 opened a new era in construction industry.

A few decades ago, grading was done manually or with tractor dozers where operator skill was important for accuracy. Advanced technology has made the grading work simple by giving option of automatic slope and elevation offsets. GPS navigation and machine guidance systems have reduced the amount of external surveying required.

Almost every construction project or site preparation requires some kind of grading and compaction. The Indian contracting community extensively uses the graders and compactors for various purposes based on size and extent of projects.

Why vibratory compactors over static ones? What is the vibration effect in compaction over static loading?

Static compactor functions with its own weight and hence compaction is confined to the top soil layer. Vibratory compactors use a mechanism to create a downward force in addition to the machine's static weight thereby affecting the top layers as well as deeper layers. Vibration moves through the material, setting particles in motion and moving them closer together for the highest possible density.

To what extent does the soil condition determine the selection of compactors?

The desired level of compaction is best achieved by matching the soil type with its proper compaction method. Clay is cohesive; its particles stick together requiring high impact force to compact. Hence, the sheep-foot roller is the best choice. Best compaction of granular soils is possible with shaking or vibratory action. For mixed type of soils, it is a good idea to choose the compactor appropriate for a larger percentage of the mixture.

What is the return on investment on a compactor and on a grader?

To have maximum return on investment, equipment should have maximum productivity and less rework. Production cost depends on depreciation, maintenance, fuel, working hours and labour. Smaller machines cost less in terms of ownership but more in labour and vice versa. In general, for each situation, one should study equipment productivity and try to strike a balance to get better value for money.

Could you tell us about the density achievable from the range of compactors? What determines the maximum achievable density?

The maximum achievable density depends on fill type, compactive efforts and moisture content and it varies from 2.1 tonne/cu m for well graded gravels to 1.5 tonne/cu m for highly plastic clays. Most of the compactors can achieve maximum fill density with different compactive efforts and efficiencies.

What are the variants in compaction?

The variants in compaction are soil type, moisture content, lift or fill thickness, compactive efforts or number of passes of compactors.

Selection Criteria:

A selection criterion for graders and compactors is given below:

? Size, weight and machine power.

? Steering, direction control and maneuverability.

? Functional automation.

? Multi-tasking machine with various attachments.

? Maximum possible thickness of the lift (for grader).

? Accuracy of the grading (for grader).

? Range of vibration frequency (for compactor).

? Working and downtime.

? Ownership and maintenance cost.

? Availability of trained manpower to use the machine.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com